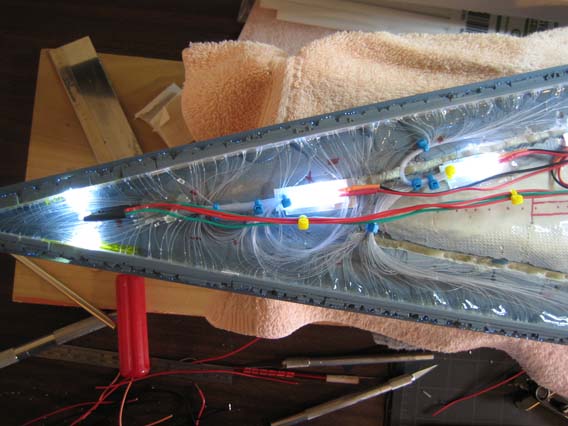

Bundling fibers into place. A toothbrush was handy to “comb” the fibers into place. Everything needed to be mounted down to the lower 1/2″ of the hull because the upper cities would require all the remaining space in the body cavity.

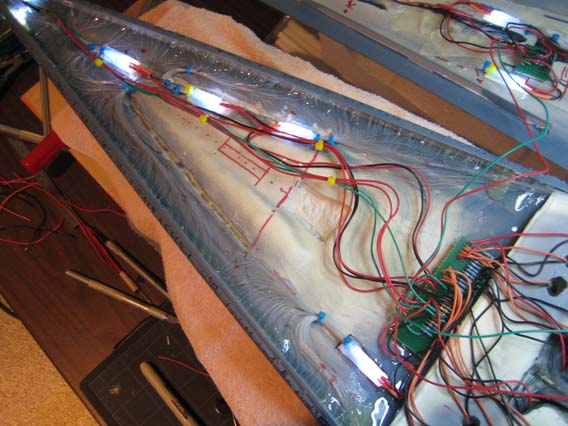

Circuit board for the lighting placement, more projector mounts.

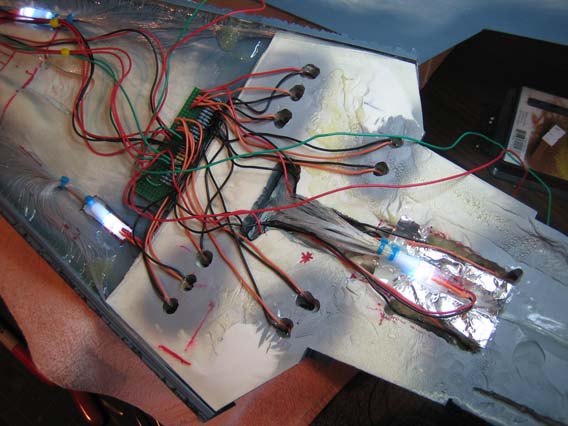

I found some great aluminum tape (usually used for ductwork) that helped to seal projectors so that there were no light leaks. It turned out to be very helpful because the LEDs were so bright that they leaked a LOT of stray light. Anything that wasn’t totally sealed (like an unpainted glue seam) would show light behind it. The tape is easy to shape, and unlike paper tape won’t dry out and crack.

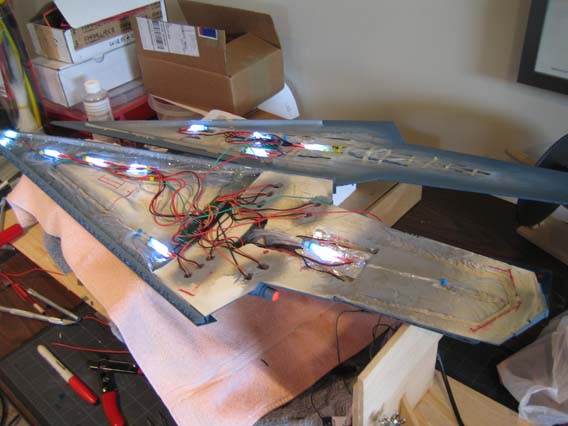

A final light test shows that all the electronics are working.

Comments are closed.