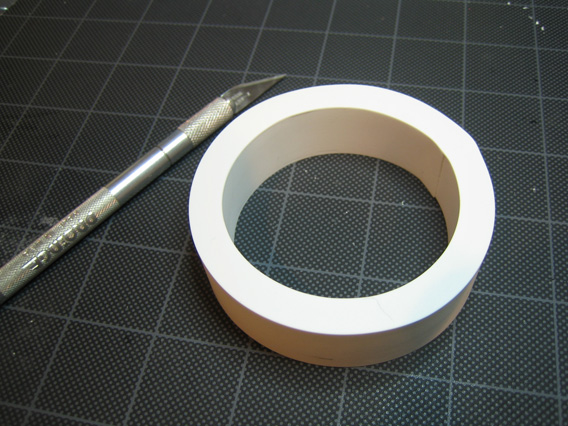

I built a full scale hollow ring prototype from styrene sheet plastic as a positive full scale ring and finished this perfectly smooth.

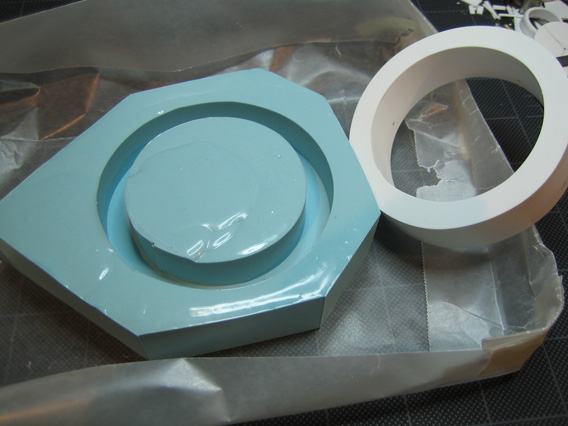

After building a mold box from styrene and locating a proper mold release agent, I poured and molded a proper silicone negative mold.

I decided to use an “open-face” mold as opposed to a two-part, sealed mold because it would allow me to better control the temperature of the epoxy during the curing process. I made the The prototype (and silicone mold) are therefor approximately 1/8″ deeper than the final ring to allow for later polishing. I used Smooth-On’s Oomoo 30 Silicone rubber–I recommend it highly. Good viscosity and tear strength and very easy to manage when it comes to bubbles.