I had dreamed of building a Terminator T-800 arm ever since I saw this scene in Terminator 2 decades ago. If I was going to do it, I didn’t want to build a kit–I wanted to create the entire thing from scratch and as visually accurate as possible to allow it to still move, yet match the movie prop. The two were sometimes in conflict with other.

Having done a lot of resin work in the past, I considered machining the parts from machinable wax then casting in resin. Since there are no duplicate parts anywhere in the arm using castings wouldn’t be efficient. Casting is ideal for multiple parts that are identical so it seemed like overkill in this case.

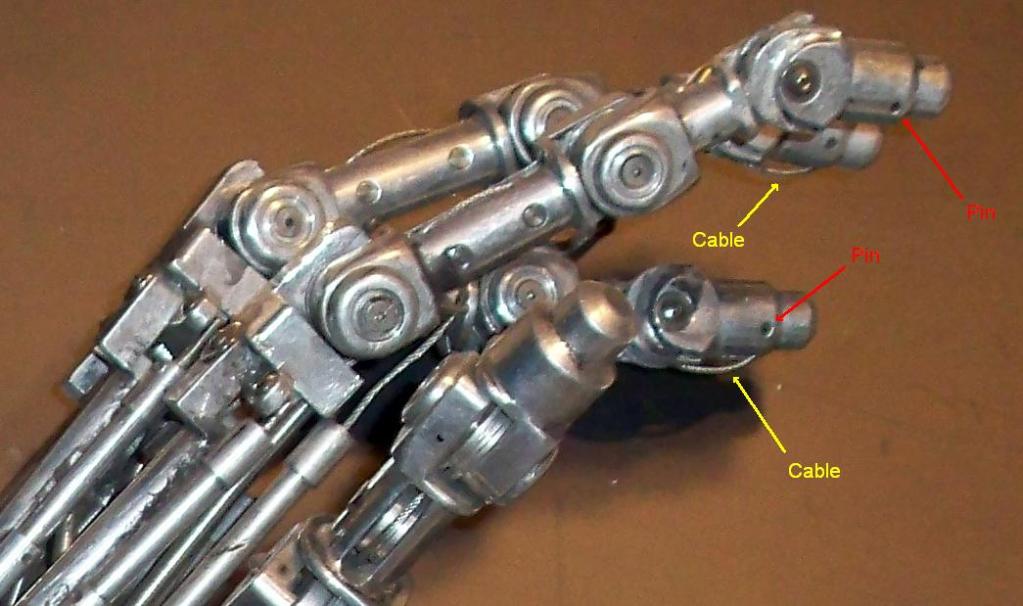

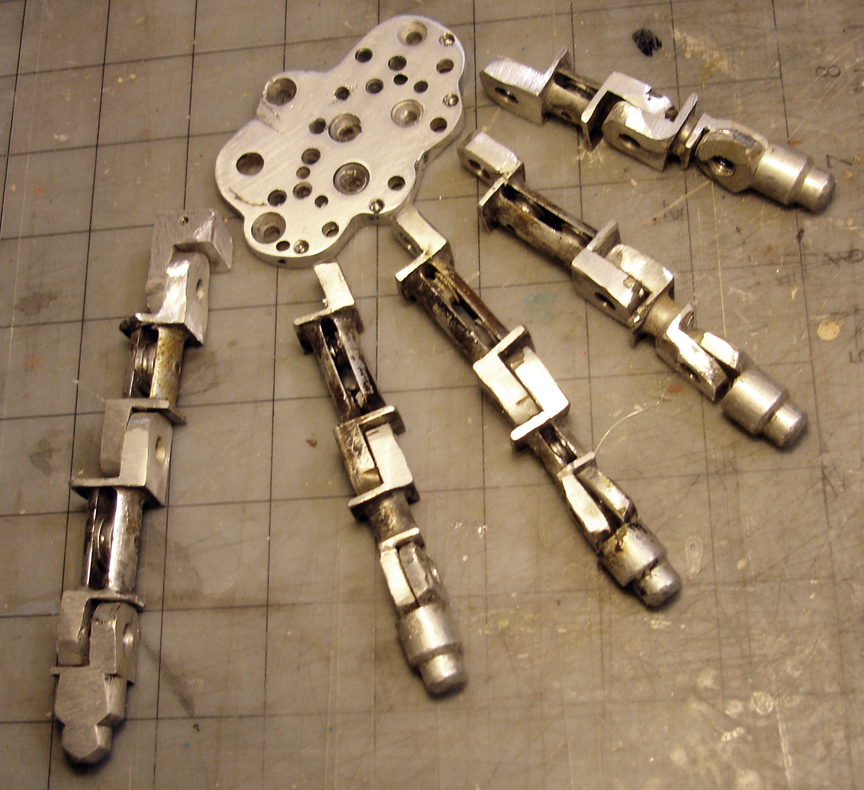

I originally decided to approach the project as a buildup in styrene and resin. First I’d do a prototype of one phalanx (a finger bone) of the index finger of the hand. This would allow me to test the strength of the build and the epoxy & glues I’d be using.

I found someone on the internet that had access to the original Terminator props and precisely measured them, transferring it all into some precise drawings. In all there were nearly 60 pages of sketches.

I started the research and development for the project in October of 2012 and discovered a lot of information about the various props used in the Terminator movies. The actual choice of which arm I would build was a bit vaque until the research was completed. It took around 3 months to gather all my sources, learning what was incorrect information on the web and what was accurate.

I’ve broken the project blog into several categories based upon my attempted approaches and final builds. Hopefully it will prove entertaining if not educational. Several people have built arms since mine based upon discussions they have had with me that spurred them to their own projects. Children of the Arm, as it were.

Most of the Shop projects on this blog are a result of the learning experience I spent on the T800 hand. Learning techniques, building my own tooling, restoring old metal tools that I could use. An expert metal worker could probable have done the hand in a week; I had to learn and build everything along the way. These distractions, while time consuming, helped me with the techniques I would need as I built the hand. I’m nothing if not very patient.

This shot from Terminator 2 revealed many differences from arm in the first Terminator film. This spurred me to serious research into the various props. Here is a summary of what I learned. The very nature of the web being that ‘everyone with a keyboard and opinion is an expert’ must be remembered, and I did my best to sift through to as many facts as seemed verifiable.

What I can tell is that there were several skeletons and/or arms made for each film so it will always be debatable as to ‘which was which”.

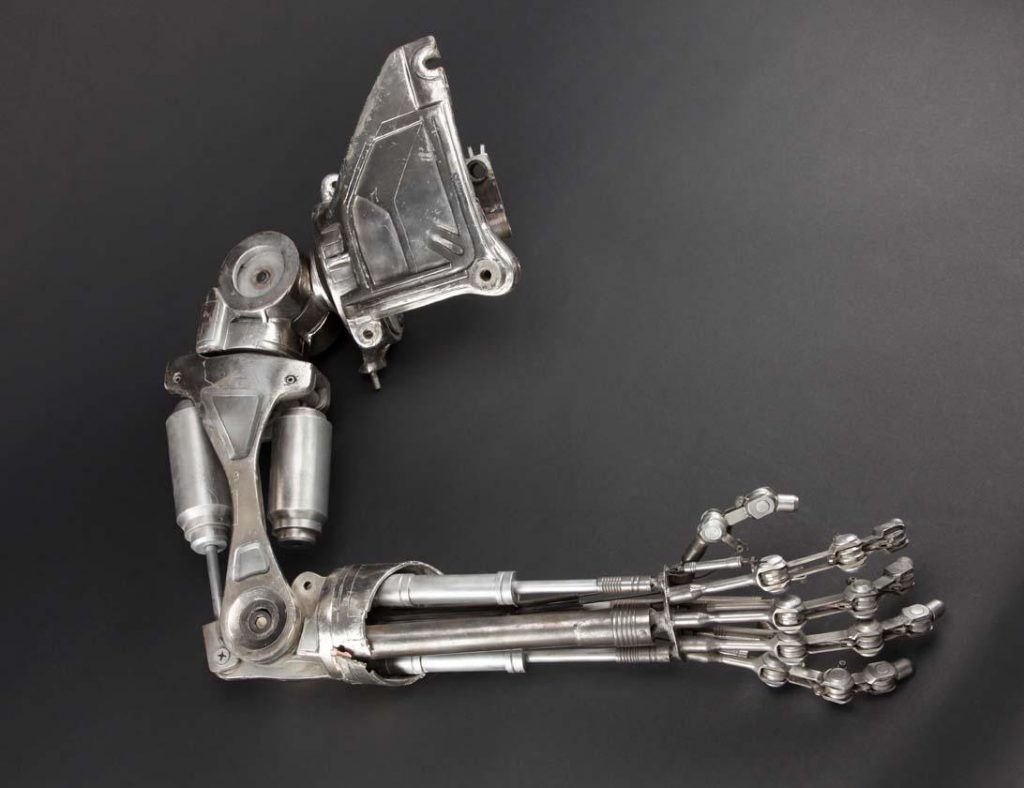

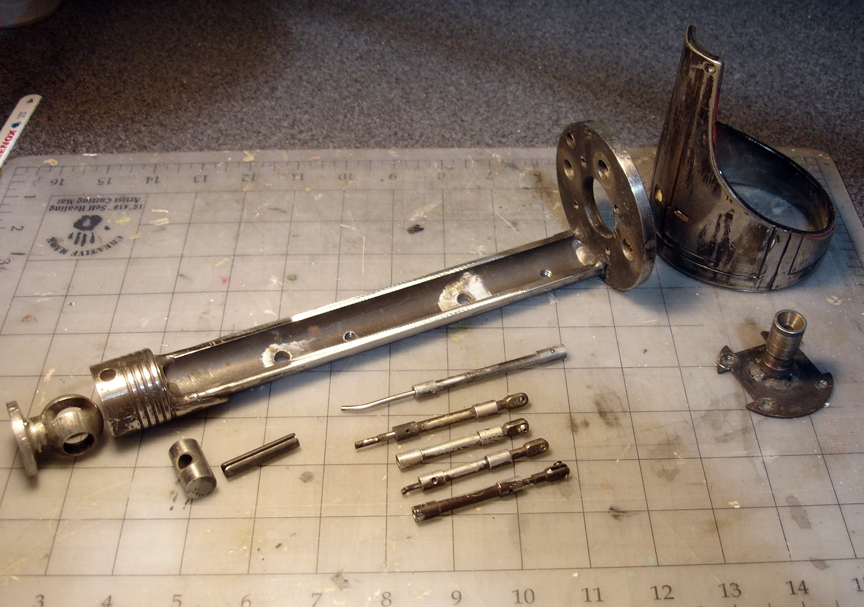

The original terminator arm was created for the first movie. For the most part this arm was made from what looks like steel and aluminum and many parts were ‘pressed’ or ‘bent’ into their final shapes. A few select pieces were cut from existing devices such as engine pistons.

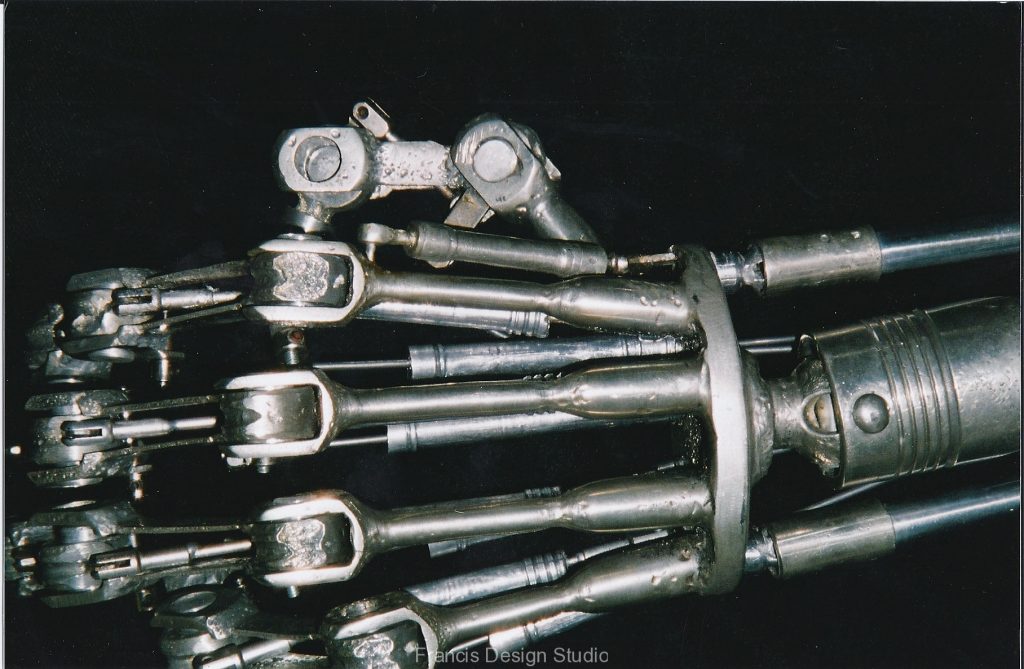

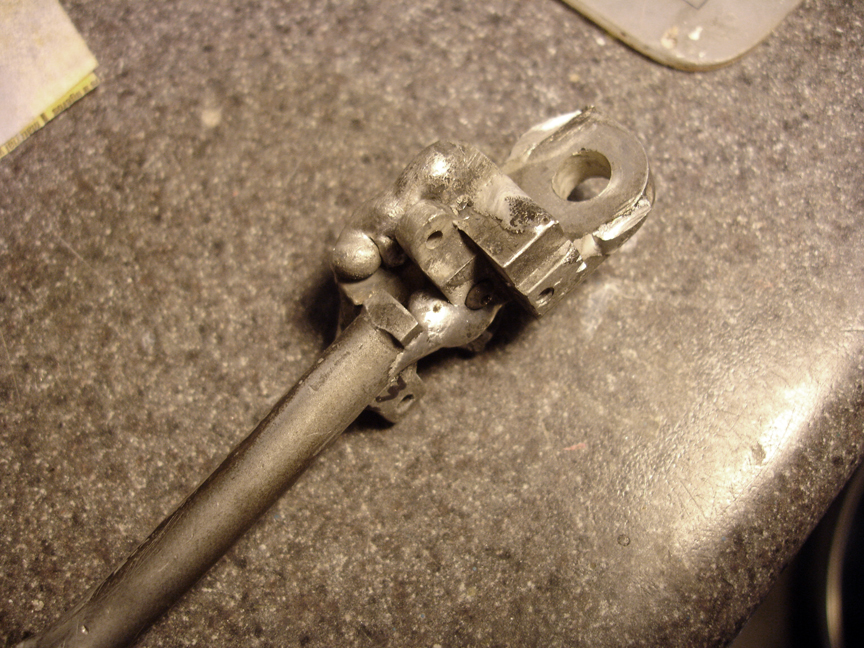

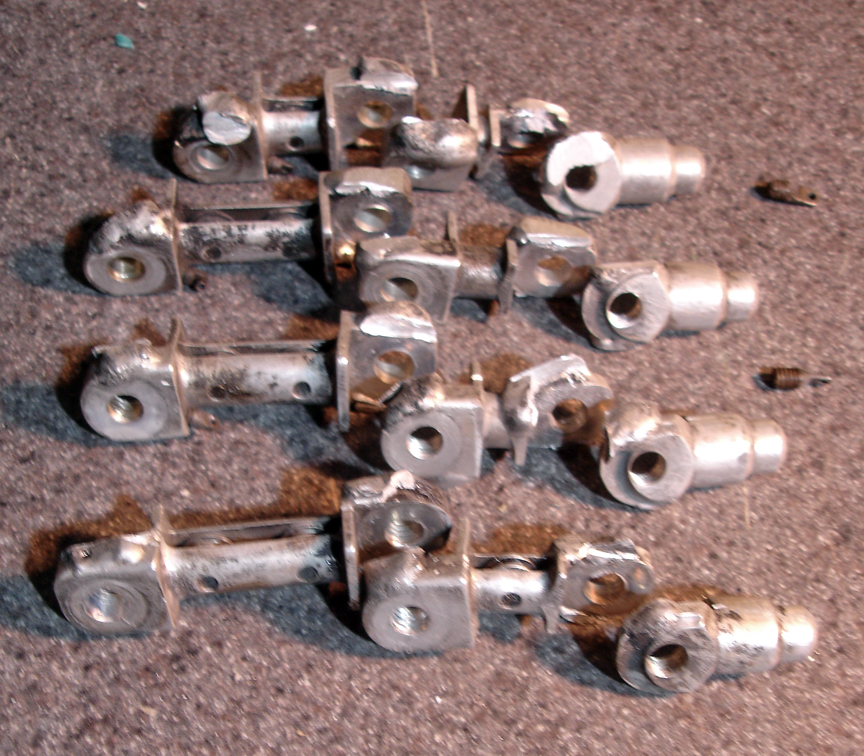

You can see much of the damage inflicted on the original props during shooting and afterwards. ‘Blobs’ where pieces were welded quickly in order to get through a scene are apparent in the knuckes that are now permanently fused together. The first film’s prop is much less detailed than that of the second film. Interestingly, the wrist joint and three forearm piston muscles are very similiar between films. According to sources, the original arm was not tripled chrome plated. Some parts where steel, and you can see many of the ‘smaller muscle pistions’ of the fingers were actually stainless steel control rods used in radio control model airplanes. Most of the steel parts have a reddish tint to them in these photos as they have begun to rust.

Once the Terminator 2 film began production, entirely new props were made. This arm was not triple-chrome plated either, and also contained a fair amount of aluminum. This prop was than vacuum metalized later.

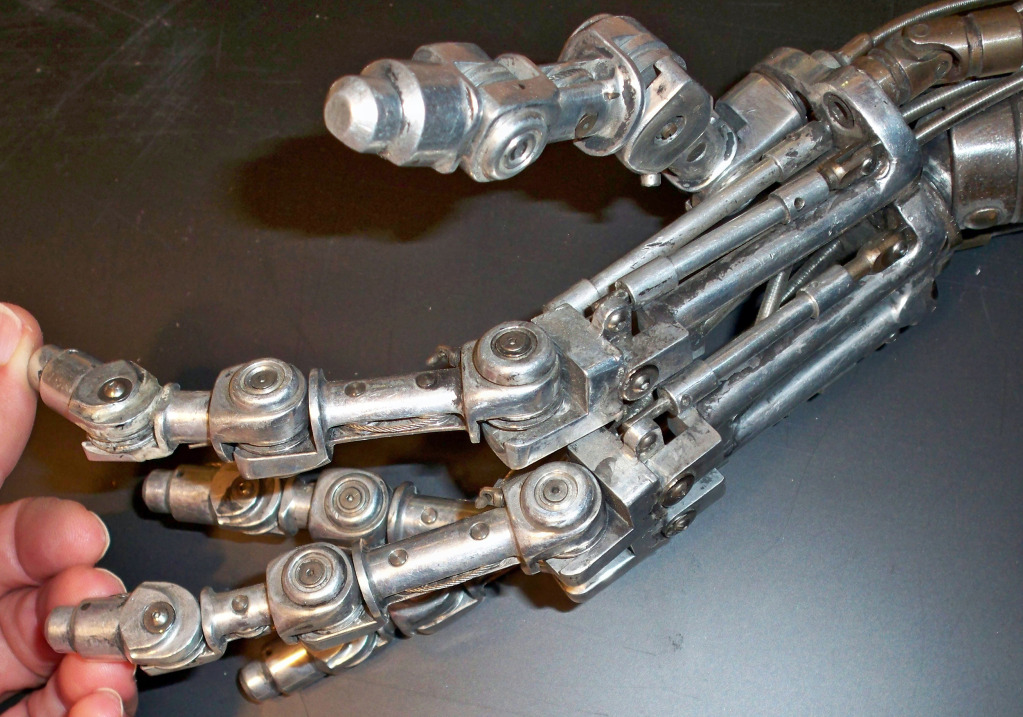

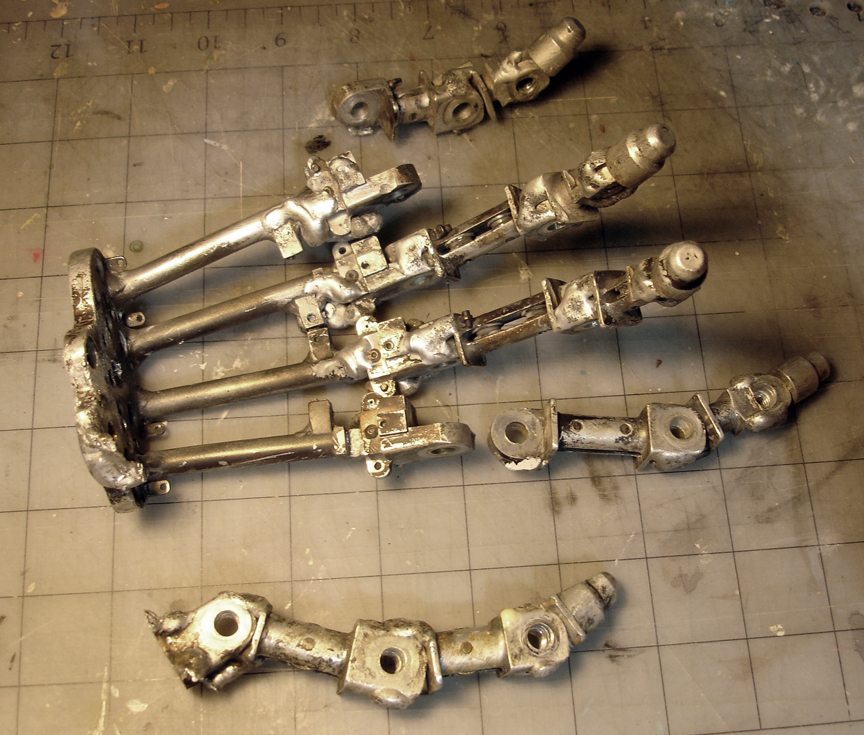

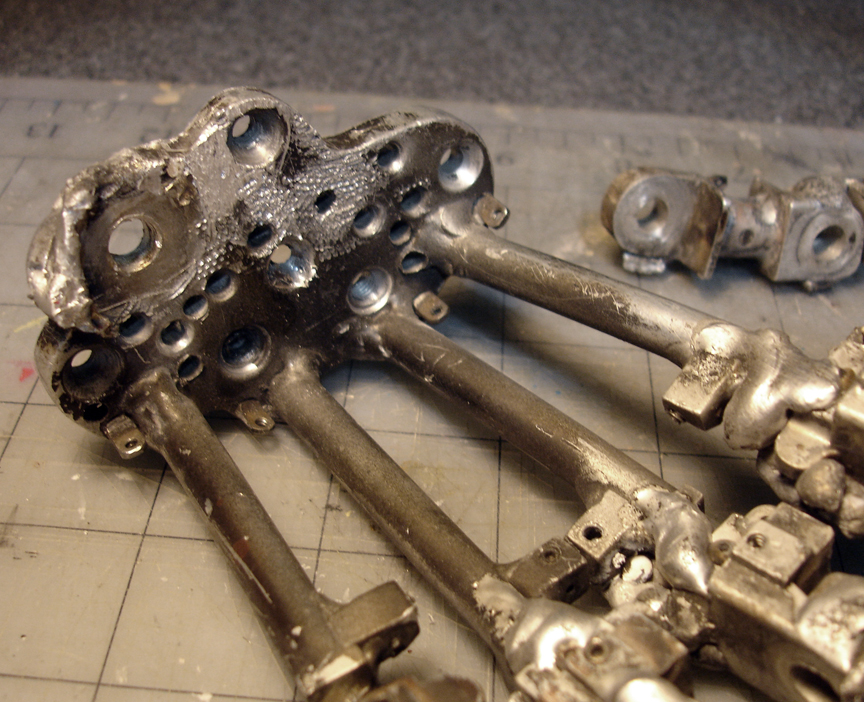

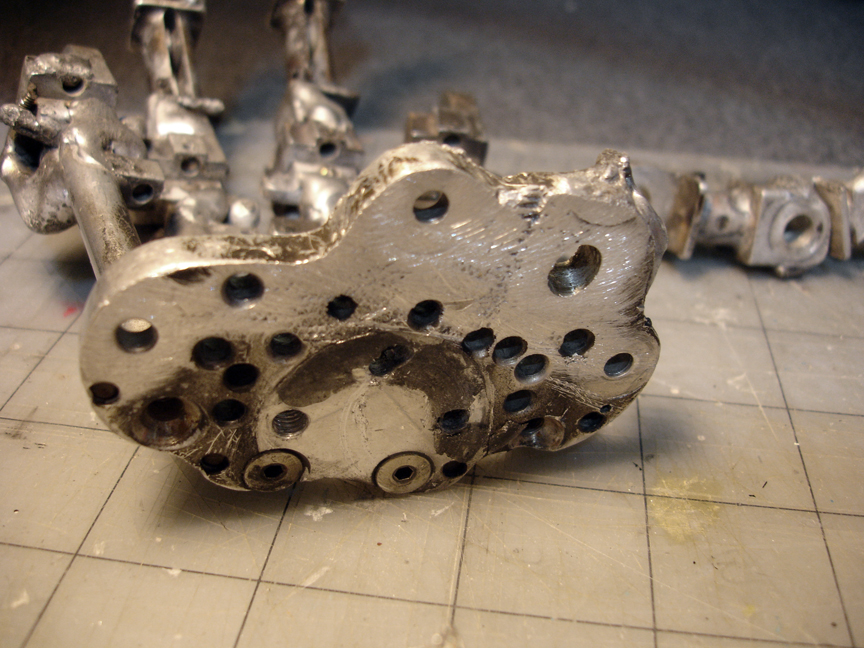

Much more detailed work went into the machining of the bones of this arm. There is also a lot of cabling through pistons and pulley, allowing some movement. Most of the axels consist of steel pins thread with stainless steel hex screws and custom made ‘washer caps’ on both sides of every joint.

During shooting a LOT of damage was done to the props. This happens during a shoot, and no one thinks twice about damaging a prop in order to get the day’s shooting completed. So if a finger breaks, someone will weld it, solder it, glue it, whatever it takes to quickly get the shot completed. By the time production is completed, props hardly be recognizable from what they once were, as evident by these photos….brace yourself, these are painful to see…..

Not only is all motion now rendered impossible, some of the pieces can barely be identified. Aluminum melted by welds, giant blobs of melted metal or solder, and large pieces ground away. It get worse….

As near as I have been able to tell, after T2 finished filming, the endoarm was sold to a company called Profiles in History along with an endoskeleton that they cobbled together as a prop for the magician Chris Angel’s stage show. The endoskeleton was composed of replica and original parts including this once fully animatronic arm. By this time it was very damaged form the heavily welded, sodered and deformed parts. Much of the detail was lost.

At this point, Lucasfilm Limited was hired to restore the arm, possible for their part in the Terminator Amusement Park Ride, but this is unconfirmed.

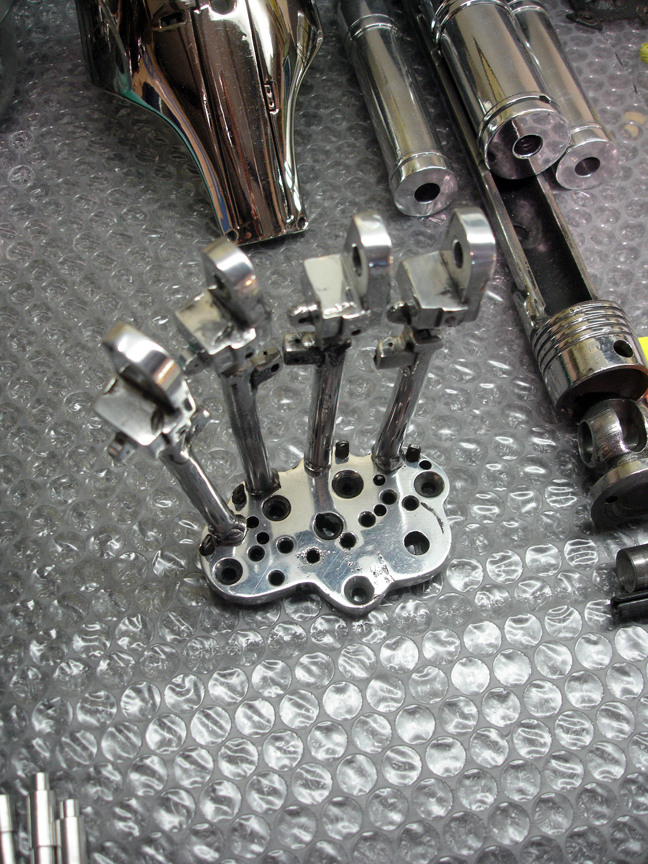

The arm was then broken down into individual components, cut apart and ground down in an attempt to restore detail. According to accounts, over 100 hours of grinding and sanding went into this. A lot of damage was done to the once sharp, details edges of the corners, as all later pictures show edges with a more ’rounded’ profile. This was probably unavoidable at this point. A lot of filing was also done into once filleted joint corners, and the entire thing was then smoothed (probably by tumbling in media).

At this point the pieces were then chromed and reassembled.

Although now quite silvery, the arm’s original glory is as close to it was before shooting as possible.