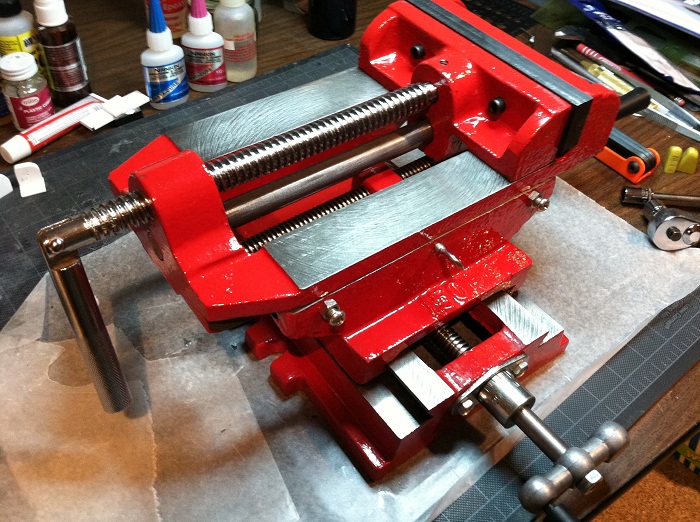

I needed an XY table/vise for my heavy drill press. After researching online some machinists steered me towards purchasing a Harbor Freight model with some caveats–these things are crap as they arrive from China. The ways have milling marks that are at least 1/32″ deep on almost every surface! Smooth motion was not in this thing’s vocabulary. Granted, I don’t expect it to be CNC-quality smooth but for $69 US it could have been better.

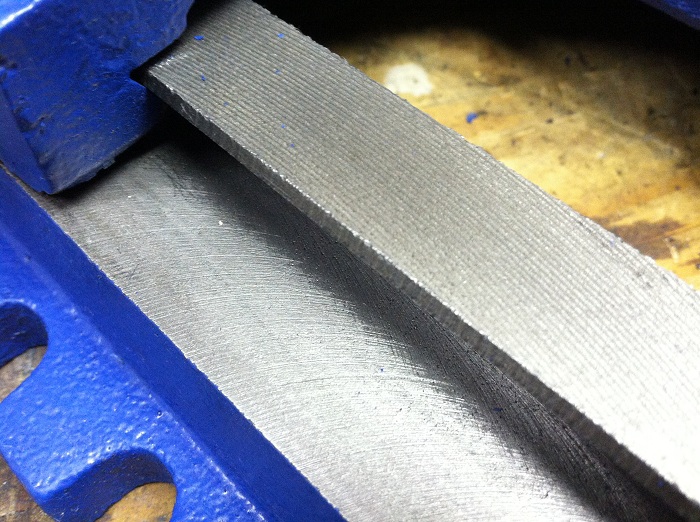

I dismantled the entire thing down to the screws and toothbrushed it with acetone to remove the nasty packing grease. Even the leadscrews had some bumps on them that were preventing smooth rotation. A file took care of the leadscrews. I then took a metal block and worked through descending grits of sandpaper from course to 1000 wet to smooth the ways. WD40 helps the wet sanding as it’s important to keep the paper clean.

Even the gibs were pretty rough and gib screw holes had metal flash on all of them that was scraping the ways. These received a good cleaning & sanding as well.

Another cleaning with acetone to remove all the fine grit I generated caused some of the cheap paint to come off the metal. A bit more degreasing and three coats of Rustoleum enamel Red and the vise is reborn in the USA.

The original milling marks can still be seen…short of milling it myself I could not totally remove them. That’s okay because too much metal removal would have made the slides too loose. The amount of material removal I did made things much smoother but still allowed the gibs enough control to be useful.