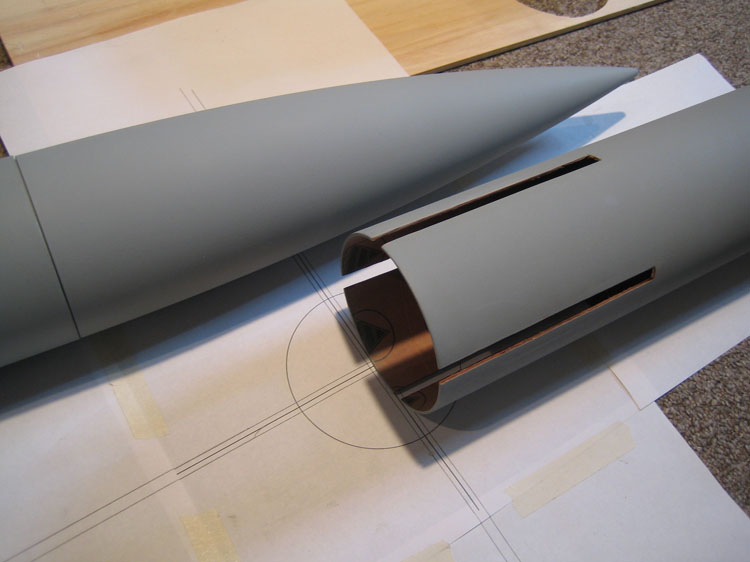

Before slotting the main tube for the fins (which are mounted through the wall and onto the engine motor mounts) I though I’d try a test. I wanted to be sure that my jib saw wouldn’t vibrate the tube too severly and shatter or crack the spiral seams I had to painstakingly filled. Glad I did. The jigsaw shook the test tube enough to rattle out some of the filler. Now that I know I tried using my Dremel with a cut-off wheel. Takes a bit longer because of the impregnated phenolic for it was worth it to avoid damaging all the labor I’d put into the seam filling. Cutting phenolic tubing is more like cutting oak than paper.

Now the tube has been slotted to the fins. After they’re completed I’ll do a dry bit of everything. A compressor comes in very handy for eliminating dust after sanding….just remember the goggles and respirator when blowing all that phenolic and fiberglass dust about.