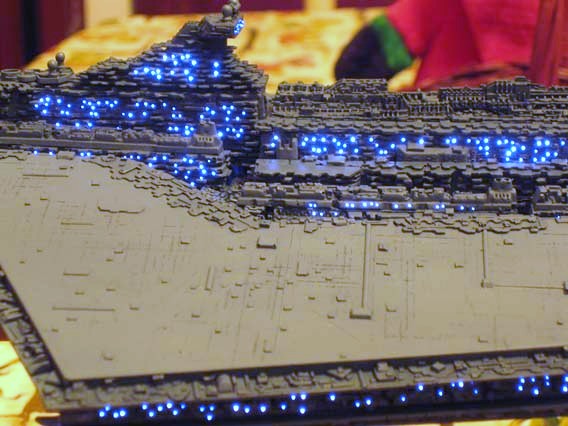

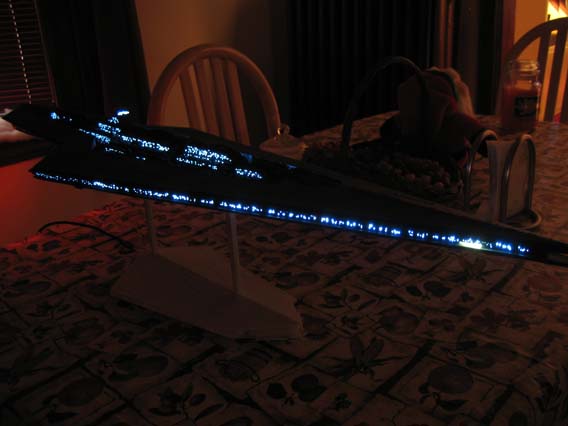

This is a log of my adventure building a replica of the Super Star Destroyer Executor from The Empire Strikes Back. There never was a consumer released model of this ship and I’d always wanted to create one. When I found out that a resin cast model was available I knew I had to build one. The resin casts were well made but I wanted to add an entirely new level of detail to it including lighting. I’d built quite a few models in the past but never anything requiring such a wide range of skills so I looked forward to the learning process. Being deeply ingrained in computer graphics I enjoyed going back to old school techniques from before CG was feasible.

I began in early June of 2008 and finished near the end of November 2008. A few hours a night here, a weekend there. A few occasional week-long pauses waiting for toys like compressors or supplies to arrive as well.

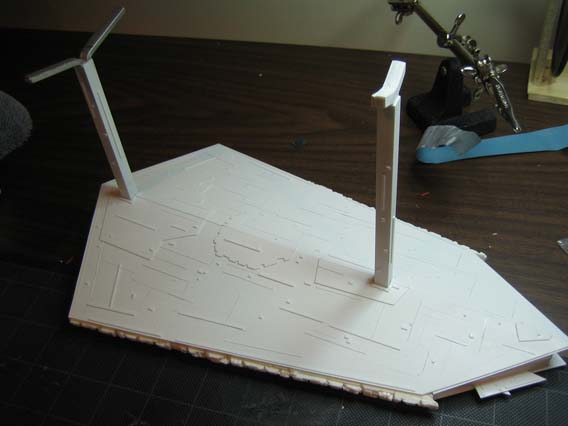

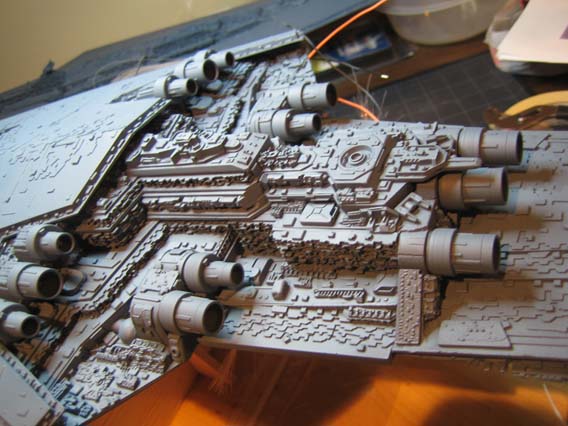

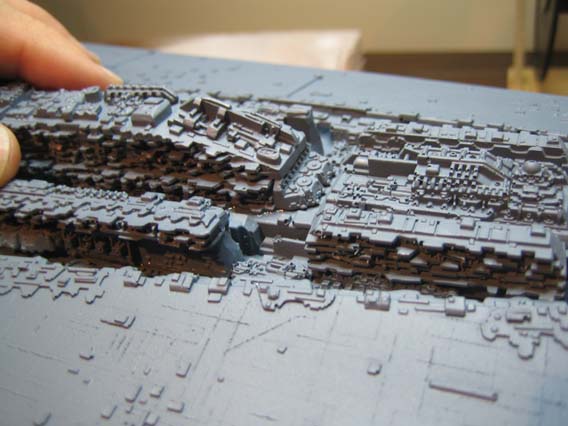

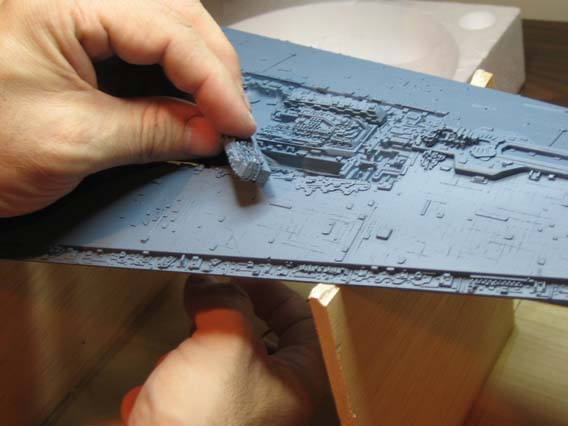

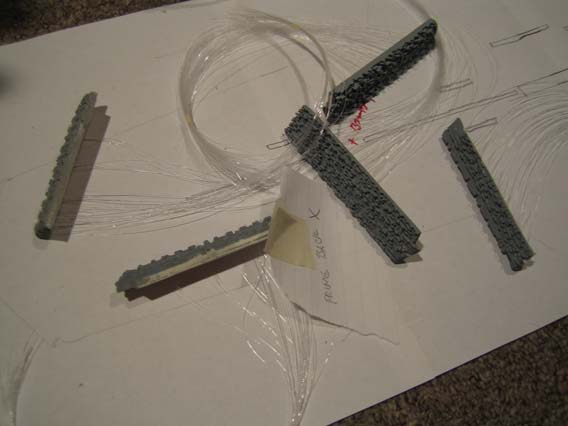

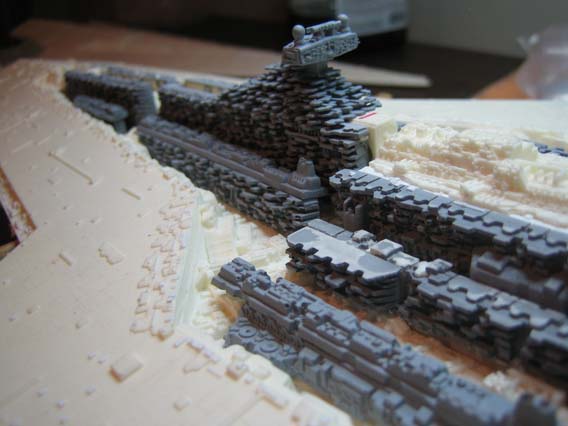

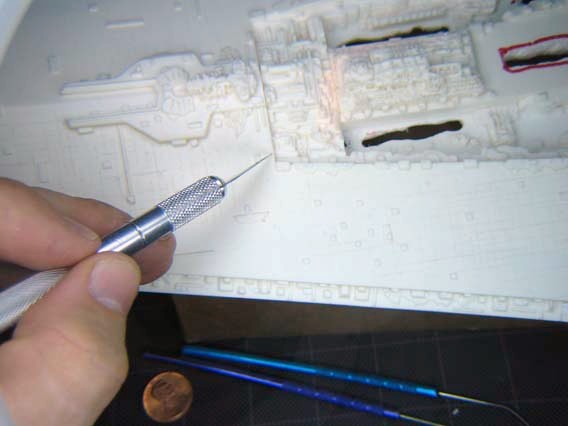

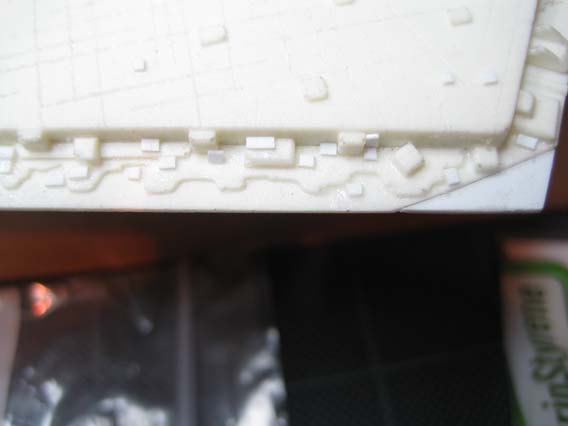

The detailed & primered hull ready for city assemblies. Because of the incredible number of surface angles, I built each city separate and painted them individually. Otherwise, I would never have been able to get paint into the detailed areas later.

The detailed & primered hull ready for city assemblies. Because of the incredible number of surface angles, I built each city separate and painted them individually. Otherwise, I would never have been able to get paint into the detailed areas later.

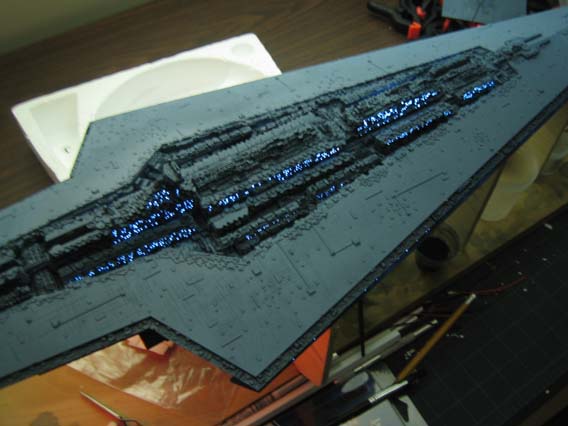

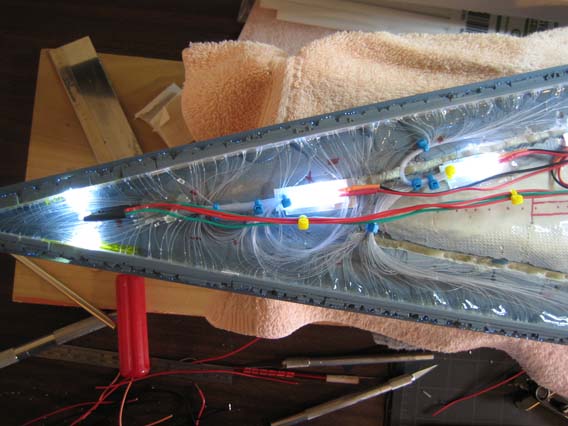

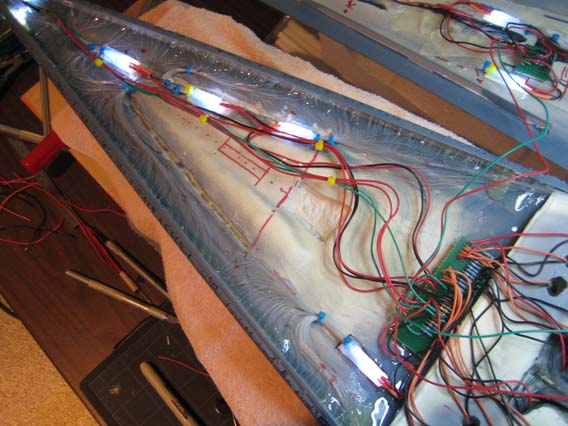

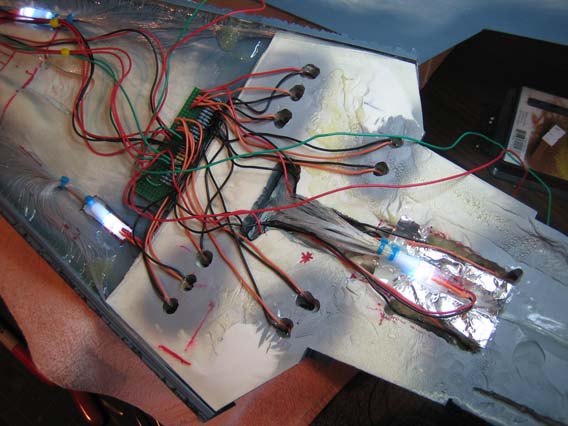

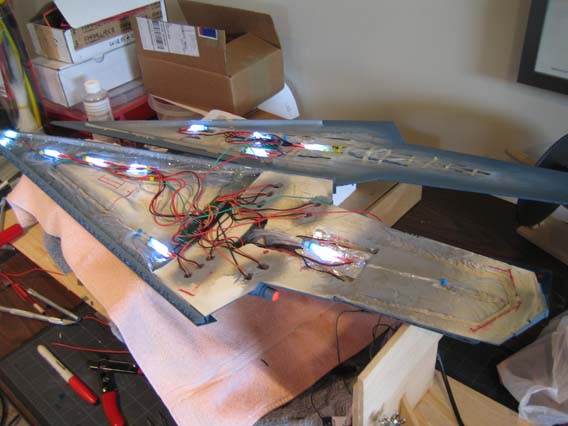

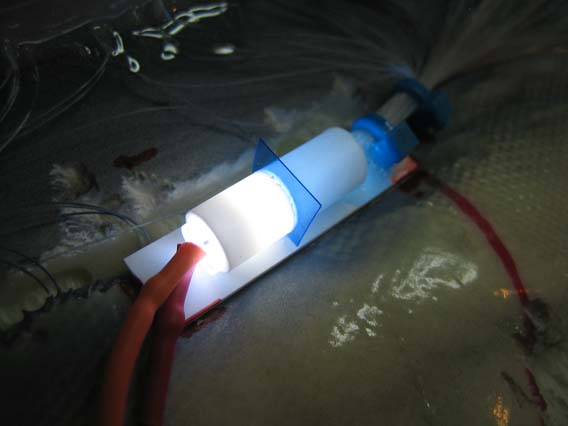

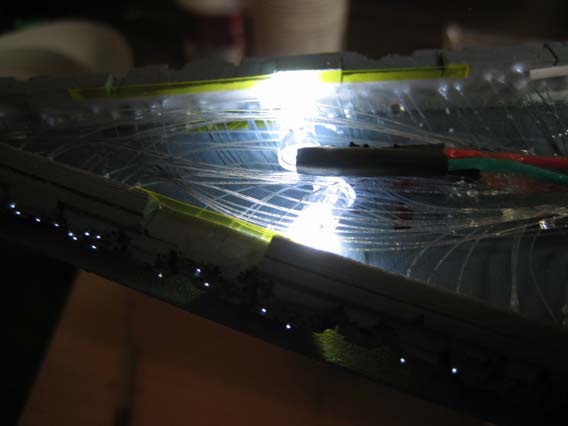

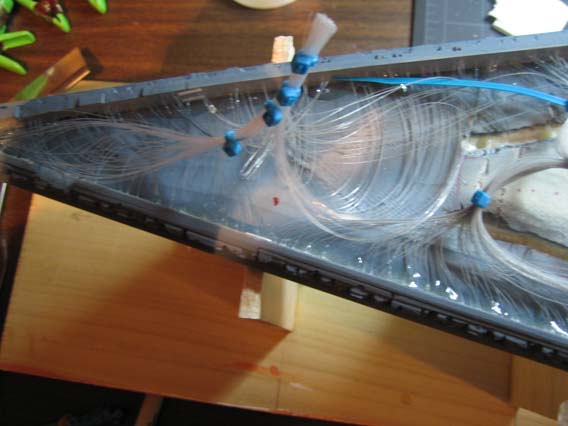

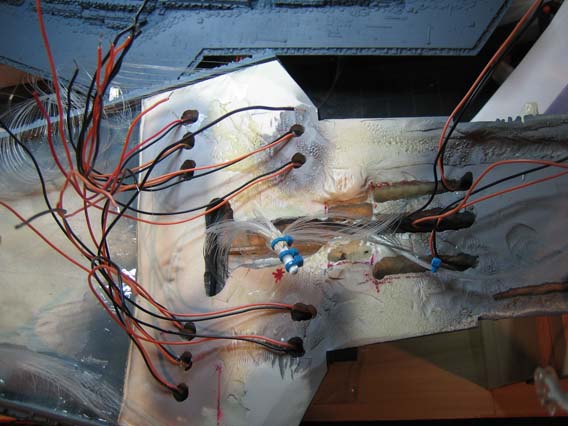

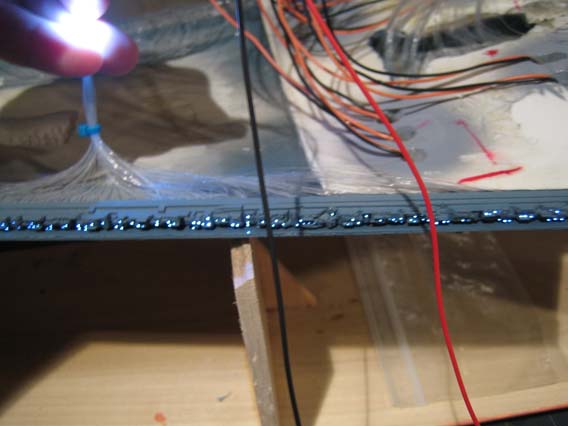

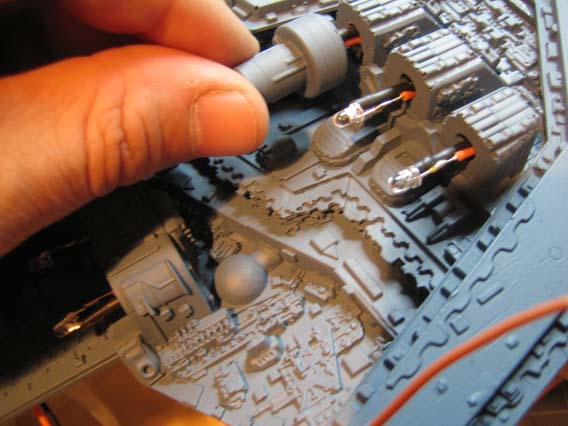

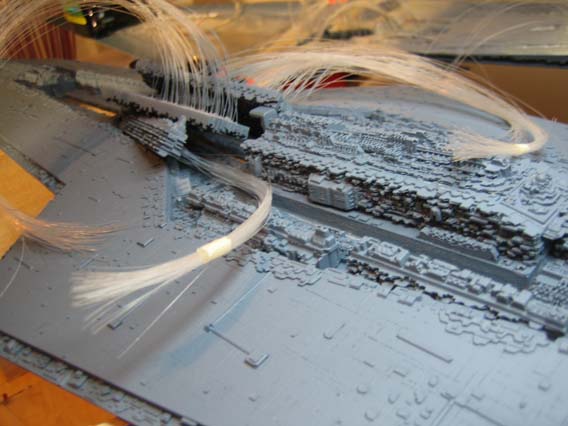

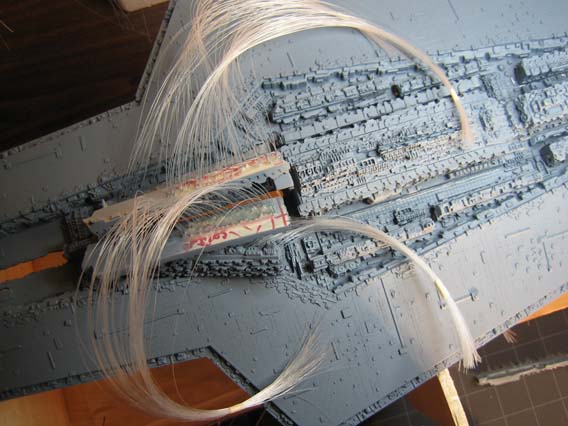

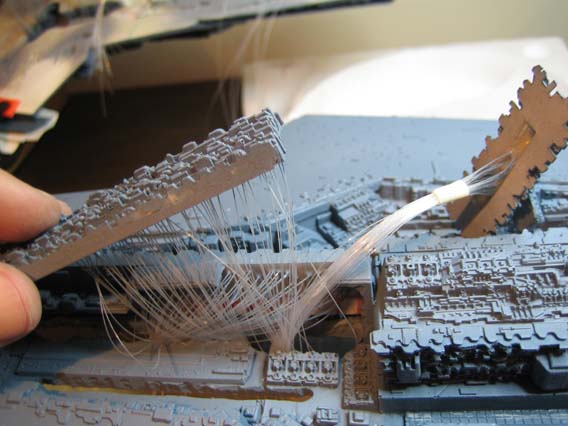

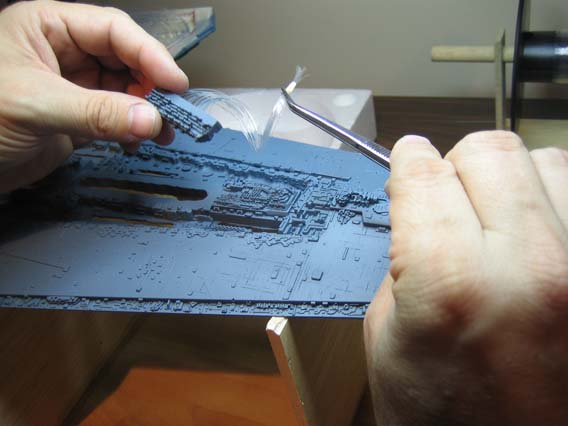

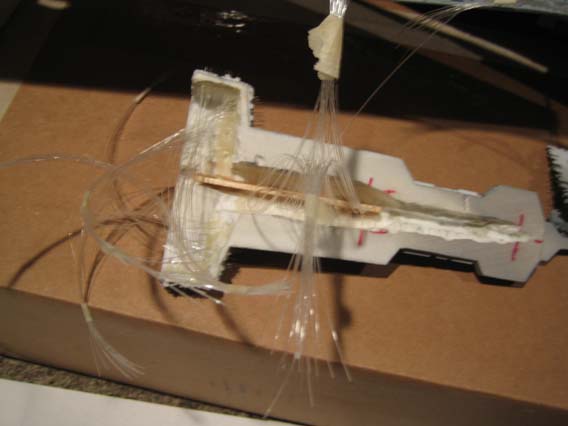

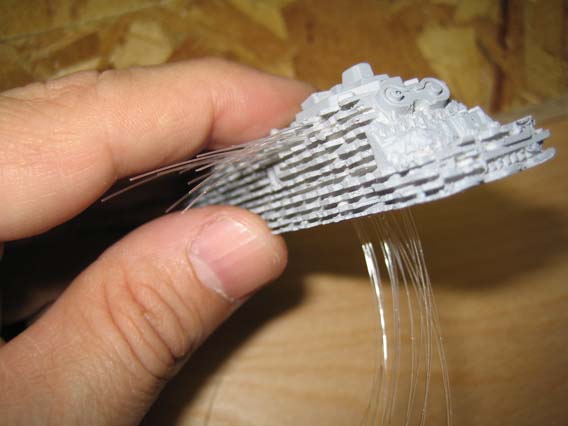

The main body uses fiberglass cloth and aluminum bars for added strength because of the thin profile. Boring passageways for future lighting has to be done around these structural pieces.

The main body uses fiberglass cloth and aluminum bars for added strength because of the thin profile. Boring passageways for future lighting has to be done around these structural pieces.