Some basic info

I don’t profess to be an expert on this stuff so I am only passing along what I’ve learned over the years.

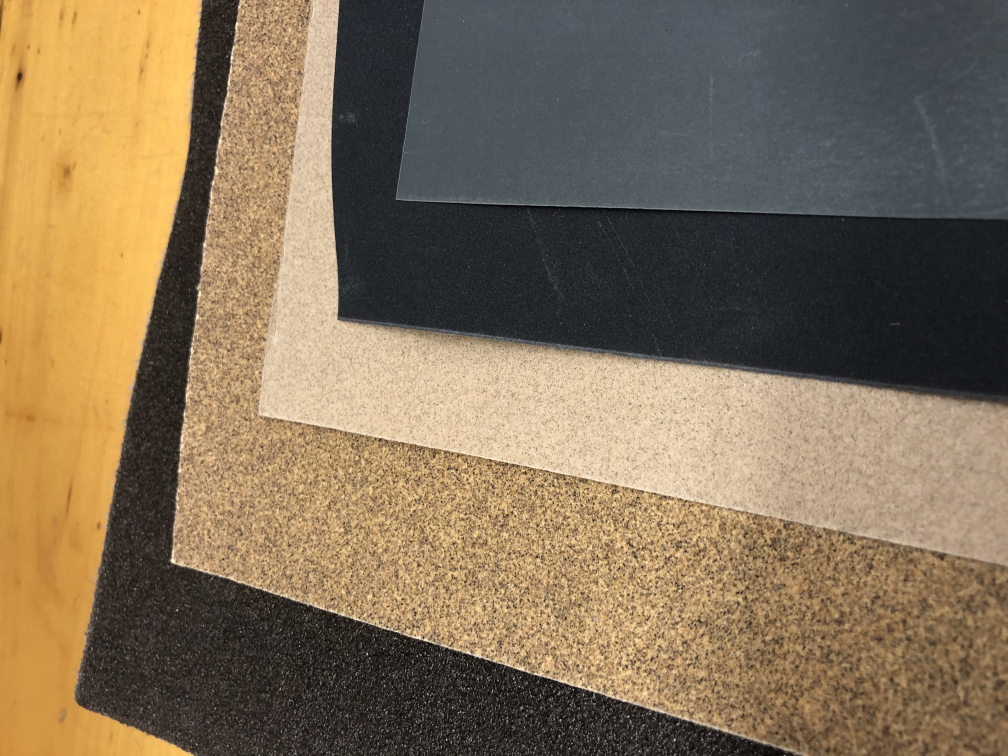

For woodworking and metalworking you generally use different types of abrasives that are specific to the job. There are many to chose from Aluminum Oxide to Silicon Carbide to Diamond. What you use depends on the project materials.

Sanding, scraping, polishing, grinding all have the same desired effect–to remove material to get the desire shape. Sanding involves scratching the material with paper to which grit has been affixed (think very tiny rocks). You use finer and finer grits to remote the scratches from the prior grit until you get the smoothness you like.

Ultra fine grit sandpaper (actually mylar at this point) can be used on steel to get super sharp edges and very flat surfaces. These are 5000 and 10000 grit and feel almost like plastic at this grit.

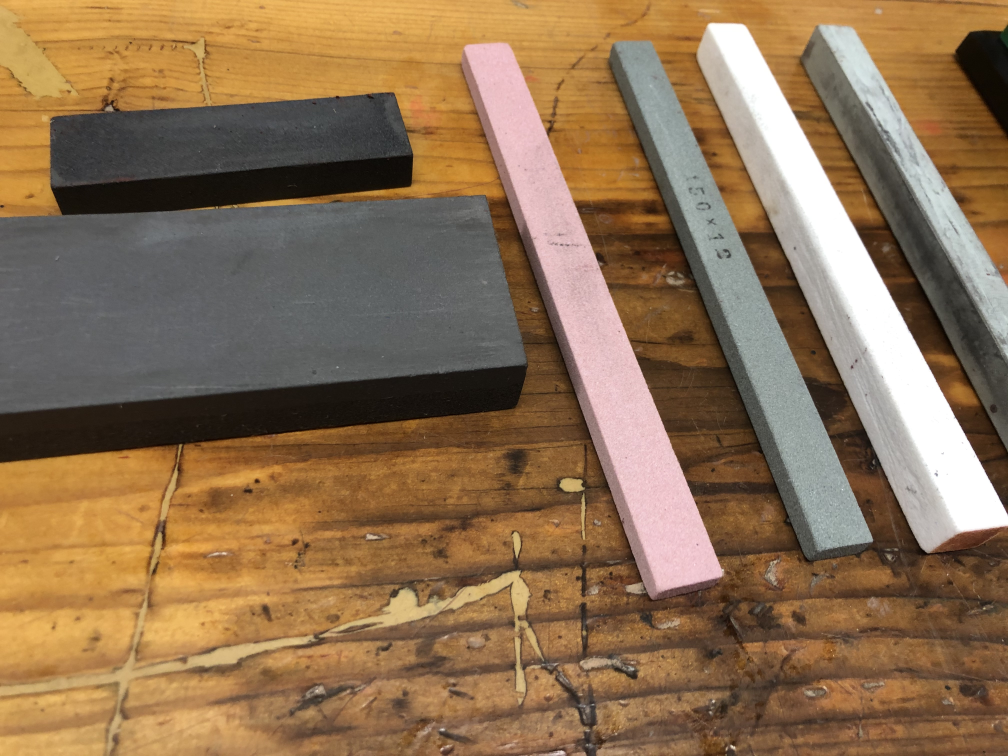

Stones that are uses for sharpening metal tooling such as drills, end mills, knives and plane blades. I use these for all of that. The flat stones are oil stones to which you add oil while grinding on them to lubricate and remove the particles during the process. When they get bumpy or non-flat from use, you grind one on another harder stone to ‘true’ it back to flat.

Diamond stones. Not actually a stone, but a metal surface to which tiny diamonds have been affixed. These are used for sharpening certain types of cutting tools such as carbide.

When sharpening, there is a point where you are removing so little metal to get a fine edge that you are Honing and approaching polishing. At this point you move from the fine stones and sandpaper to something like a strop. Some people use a powered wheel but I prefer the strop for finer control. I have three stops I made by gluing 24″ of leather to flattened wood. The first strop is “charged” with an abrasive compound.

These compounds are something like a soft wax that has been mixed with ultra fine abrasives. This is not unlike toothpaste, which is an abrasive in a liquid carrier for polishing teeth. You rub the compound stick (they feel like big crayons) on the leather, then hone the object on the leather strop several times. By moving from more abrasive compounds to finer, and then finally just the plain leather strop you hone the last of the roughness away.

The process is usually the same for wood or metal. For smoothing, start with a course grid (whatever the medium) then remove material gradually, then go to the next approximate doubling of grit. I.e. 80, 150, 220, 400, 800, 1500, etc. If sharpening metal, I usually then hone with 2000, 4000, 10,000. Then polish with compounds to the finest grit you have until you get a mirror finish.