The closest I’d ever come to working metal was owning a vise and a hacksaw. So I had a lot to learn.

I spent a few months reading everything I could about it metal fabrication, milling, lathes, saws. While I owned a nice woodshop and had done a lot of woodworking, this required an entire different set of tools and discipline. Where most woodworking accuracies were around 1/32 of an inch, metalworking relied on accuracies of at least .001″, and in many cases for this project .0001″.

I decided to work in aluminum and steel for the majority of the arm construction. I started trying to cut pieces with crazily-rigged saber saw in a linear jig I fashioned to cut 1″ aluminum bars. What a waste of time that turned out to be, causing no end of frustration. More research told me that I needed a metal capable bandsaw. It turned out that someone I knew owned an old, 1950’s era saw that was perfect, but needed a ton of restoration. I took on the project and the details of that can be found in my blog section titled “Bandsaw Restoration”. Just like that, BOOM-a couple months went in that project!

I came back to the arm able to cut metal much more efficiently.

My next purchase as a mill. I bought a Sherline 5400 manual mill and spent a few weeks learning and practicing, then started converting it to be CNC capable. I was using some off-the-shelf software (Mach 3) to control it with my own hardware circuitry and a Gecko G540 Controller/driver. I found myself frustrated with the antiquity of the Mach 3 Software and fell down a rabbit hole.

I’m certain that when it was written, Mach3 was at the top of the heap.

However, this software is buggy as hell. It crashes a LOT. Many of the ‘features’ are either beta and never finished, or assumed to work and never tests. It handles the basics fine–give it G-code and it will run–but I really wanted to use it’s Visual Basic capabilities to program my parts programmatically. The VB interface (which isn’t really VB but is actually something called Cypress Basic) is also very buggy. I think it was patched into the code to claim VB capability but never truly debugged entirely. When I inquired only of Mach3 experts about some issues I was told I “wasn’t using Mach3 the way it was intended”. That may be so, but I was only doing things the software claimed it could do. If it crashed with just a little pushing what good was it?

It took a LOT of time to make the code work and I still saw a lot of Mach3 crashes. The company that now owns the ancient Mach3 code base has been claiming (as of this writing) a new version will be out any day for the last few years….I’m thinking they had no idea what they were getting into with that project. They’ve also said that the new code will no longer support VB scripting, instead using LUA as it’s new script language. I have nothing against alternative scripting languages, but LUA?? In forty-some years of programming I’ve only seen one other application that used LUA and even they switched to Python after a few years. This is what happens when programmers make decisions that should be made by end users. What to they say about having to eat your own dog food….?

Over the course of the next few months I abandoned the Mach 3 software and decided to write my own CNC software to control the Mill. For the details of THAT adventure, see my blog entry “MillDroid”. Once again, BANG!-a few months go by as I get that project off the ground.

By now I was getting anxious to start making chips….

I could now do some simple machining, both manually and via CNC as the software I was writing began to take shape and become more robust.

I’ve been making some parallels from hot rolled steel but doing most of my cutting with 6061 aluminum. I really like the aluminum better and think it will be a better material for the T800 hand. The Sherline Mill is a very nice piece of hardware. The main thing it is missing are covers for its ways, but that isn’t fatal. I figure that by the time I wear them out I’ll want to build a larger mill from scratch.

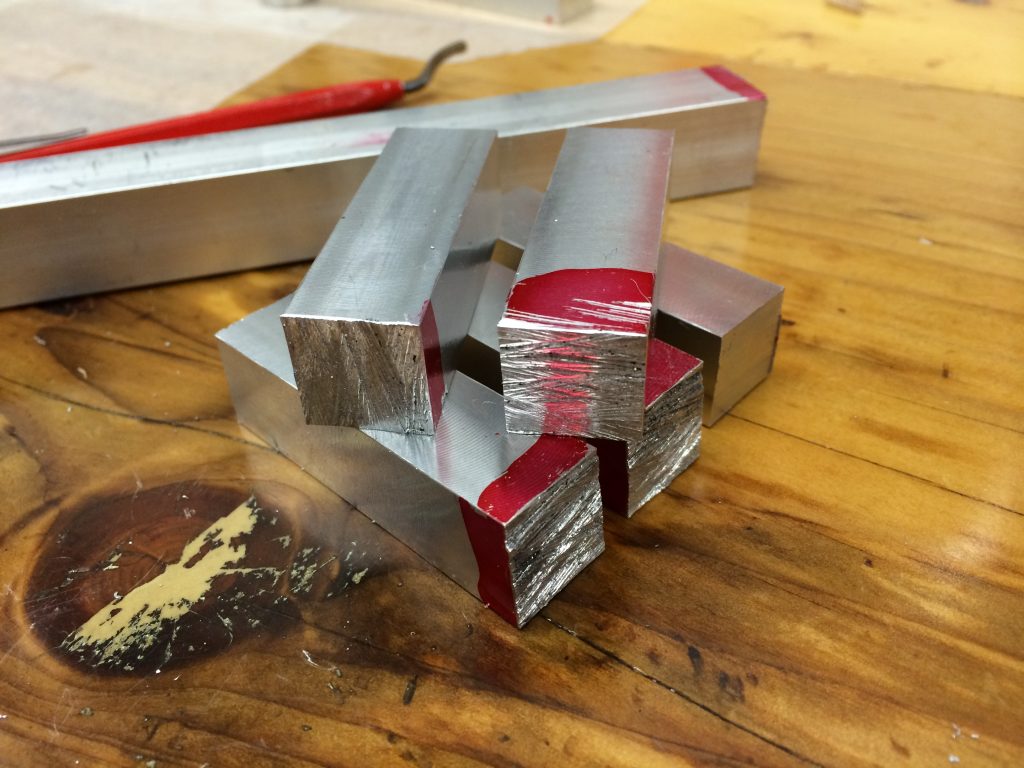

A few practice pieces from 6061 aluminum…..I have a local metal working supply shop that has a large selection of end mills in bins for a couple bucks each. It’s a great local resource and let’s me avoid shipping costs every time I need a simple tool. Need a 3/8″ double-sided 2 fluted high speed steel end mill? They’ve got 50 in stock for $3.00 each. At those prices you don’t feel bad experimenting and breaking a few end mills.

I picked up a Harbor Freight Tumbler to do some of the finishing of the pieces. Through some trial and error I found that Ceramic media left the Aluminum with a black coating (Aluminum Oxide, perhaps?) After some experimenting I found that tumbling in Plastic Pyramid media for 2 days, then walnut shells embedded with red rough for 8 hours produced a nice polished chrome-like appearance. Too long in the pyramids caused the edges of the metal to “round” more than I wanted.

The quest for walnut media was interesting. Online suppliers wanted $50 for small quantities (a few pounds) of crushed walnut shell media. An online metalworker suggested to me looking in a pet store for Amphibian/Lizard Litter used to line the cages of pets. Sure enough, they had twenty pound bags of the stuff (pure ground walnut shells) for $8.00!

The Red Rough I added to the walnut media was suggested online…..that stuff is messy. It sticks to everything including your hands. I’m going to try some tests without it and see if the difference is noticeable.

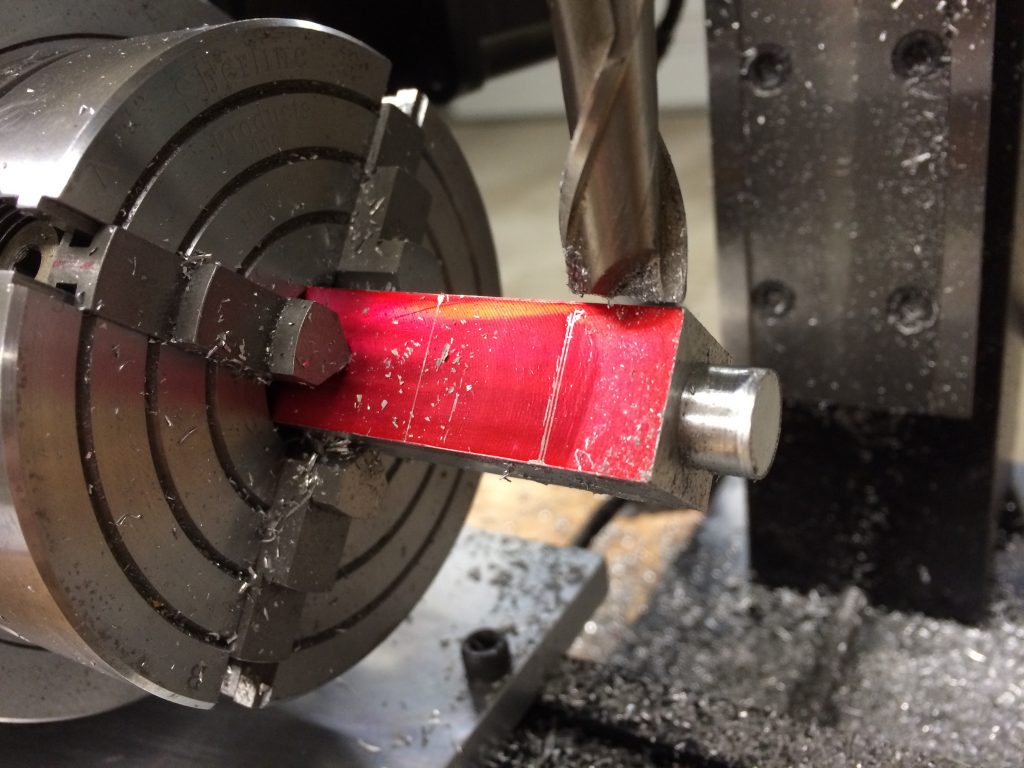

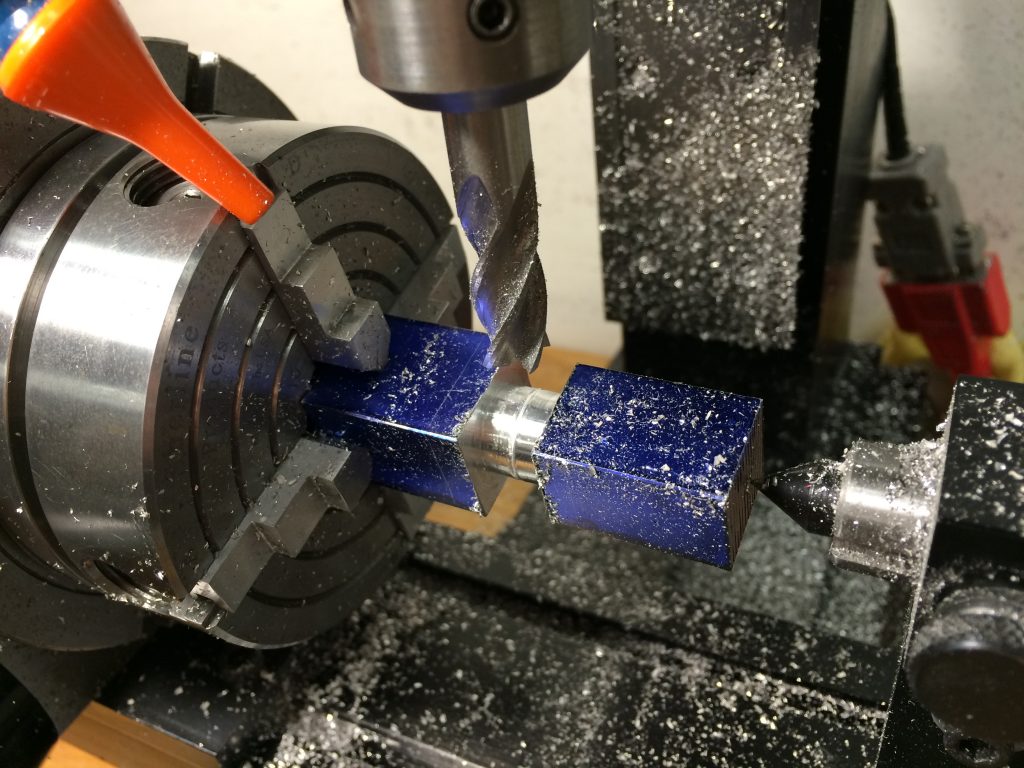

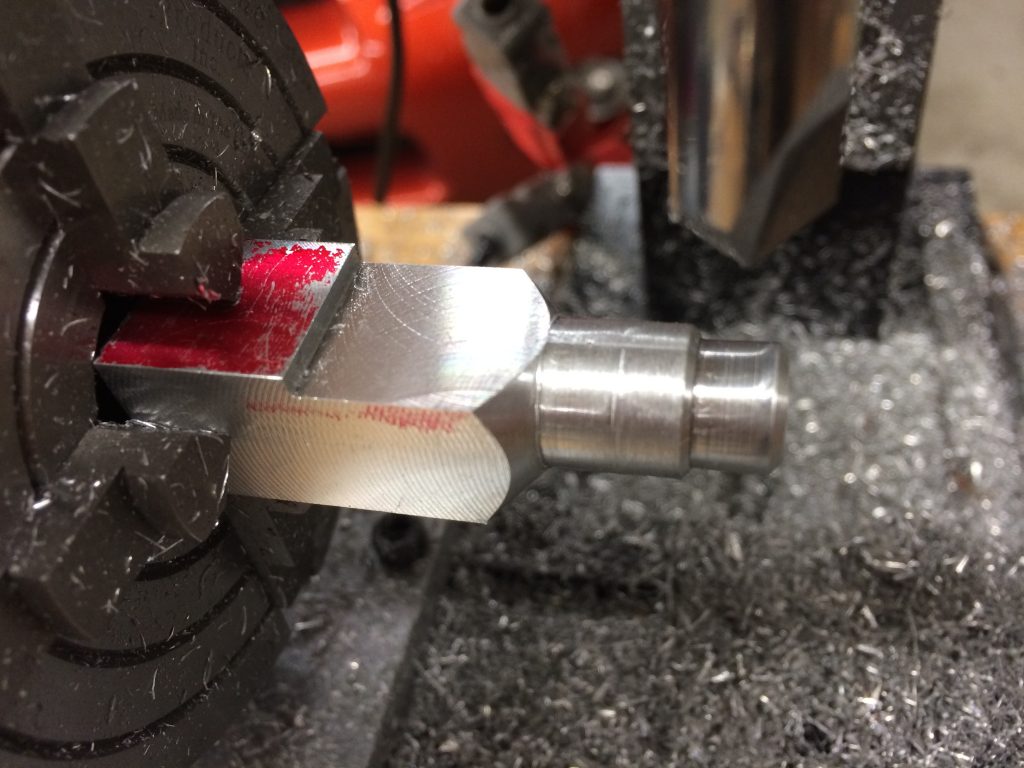

Without a lathe, I tried to be creative with my new mill, and succeeded at some things. Using a rotary table mounted 90 degrees to the spindle, I was able to write CNC code to mill the round finger bones. It was slow, but it worked!

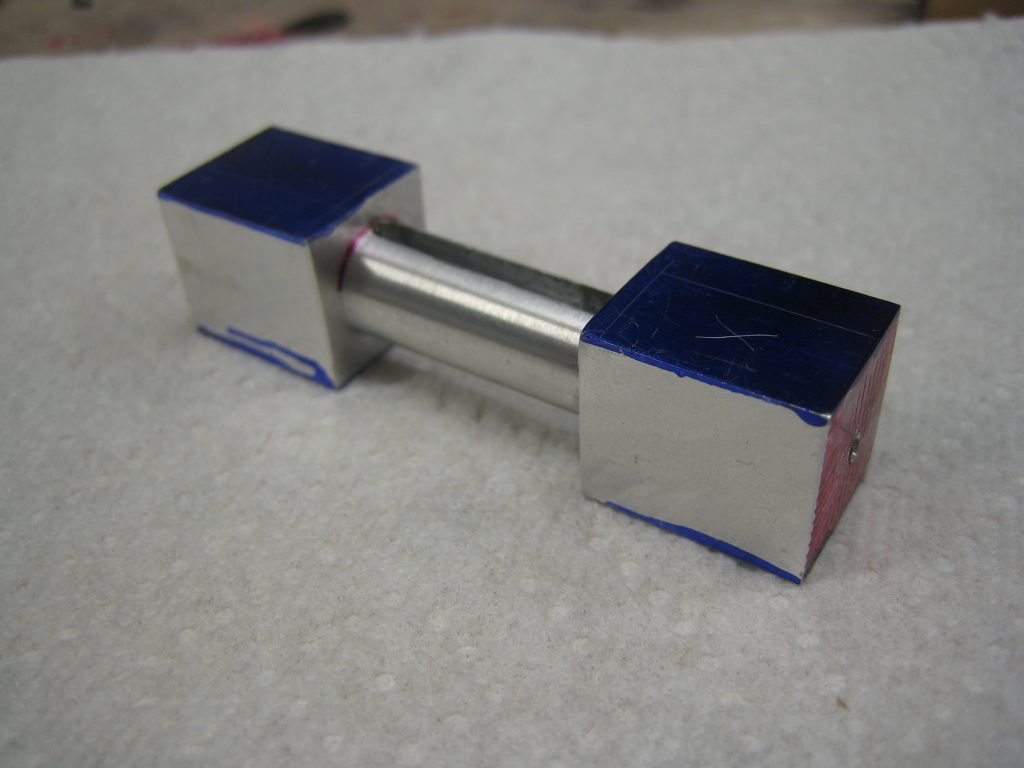

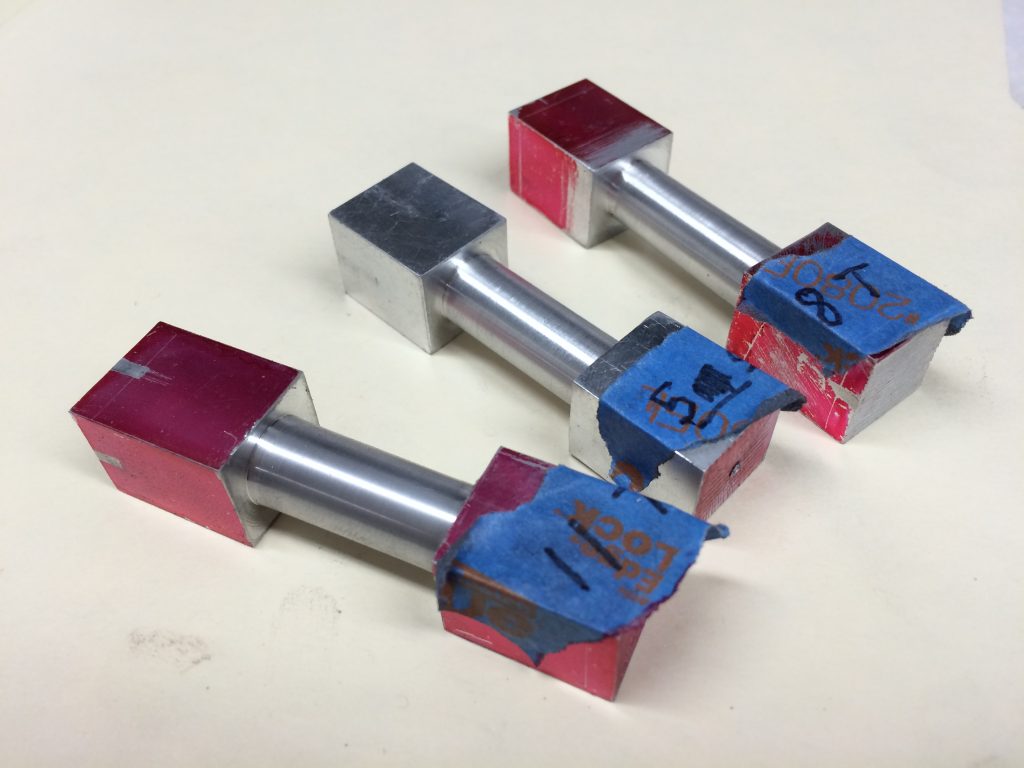

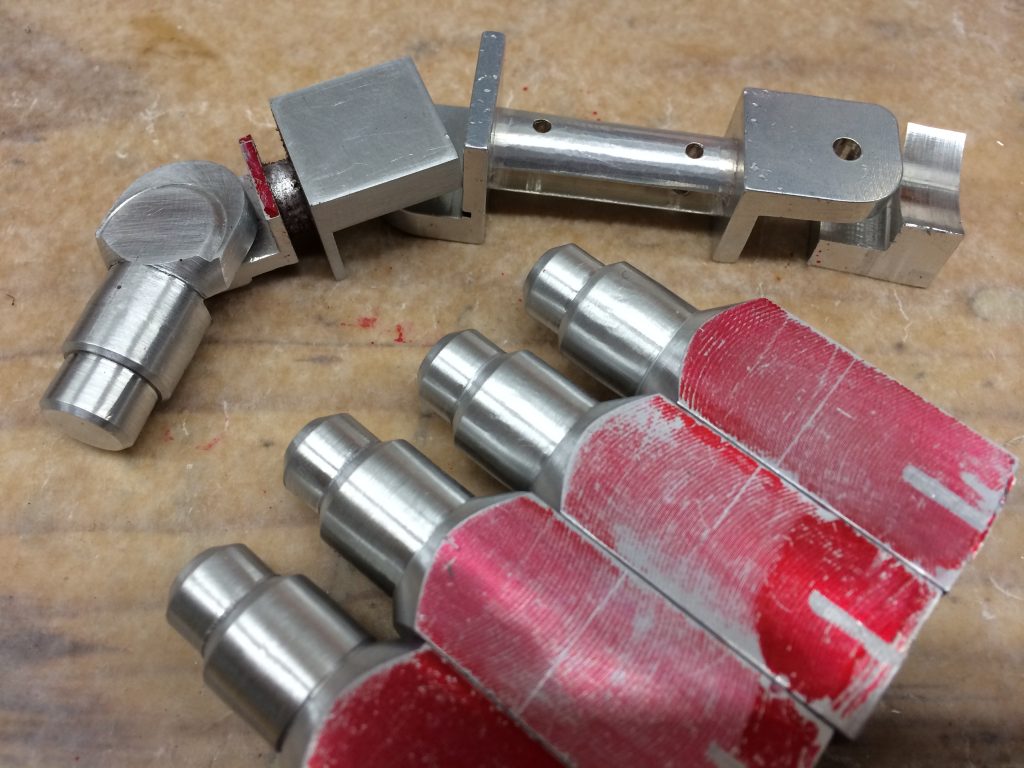

I can’t believe it worked as well as it did, but it was slow, taking hours in some cases. Not to mention how much time was lost if I screwed up a part. I called these finger bones ‘barbells’.

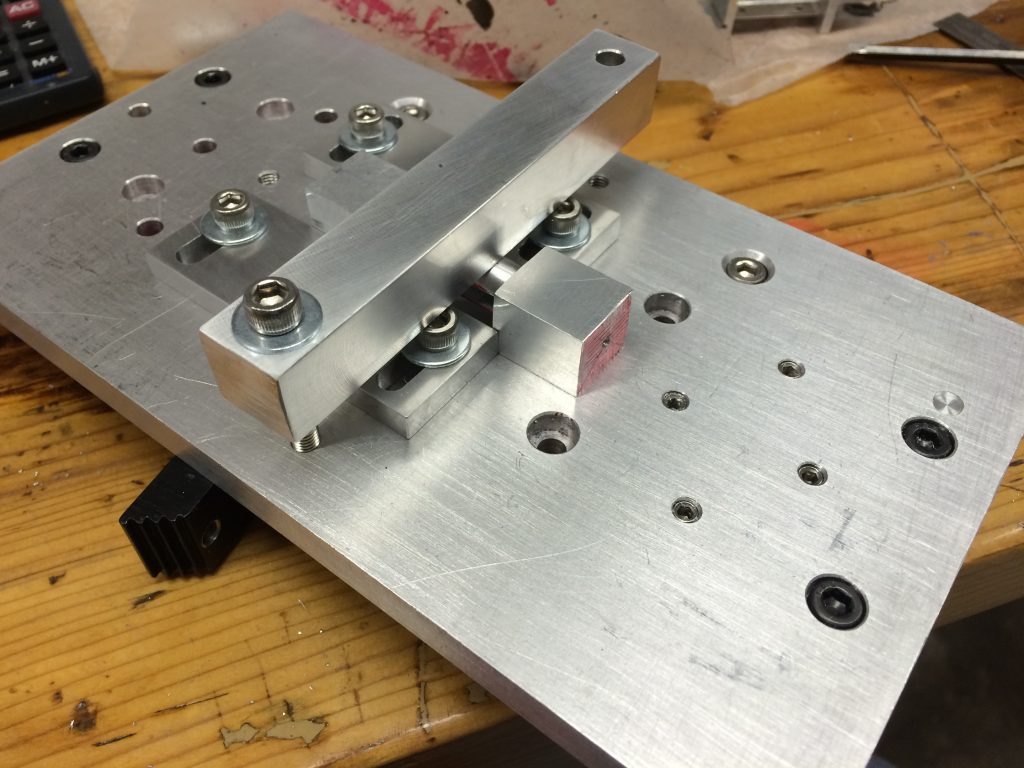

I started getting more productive once I made several jigs from aluminum to hold all these custom shapes, irregular parts. Even a single finger barbell may have looked symmetric, but all the sides and thickness of each side were different and offset from the center ‘pole’. I was determined to get the measurements perfect if for nothing else, the learning experience.

First programming lines, then block removal, then arcs, then slots….I practiced some of the basics. I wrote everything in VB/Cypress Basic and it generated the G-Code that ran in Mach3. I put a lot of error correction into the VB to catch Mach3 Exceptions. Gradually as I wrote my MillDroid application and added features I moved away from Mach 3. Slowly….

The tips of the fingers had some interesting geometry with which to deal.

With a first finger prototype nearly done, I came to the conclusion that, if I wanted to be more productive and get this thing finished within the next twenty years, I would need to invest in a Lathe.

So I splurged and bought a Sherline 4400 manual lathe and (you guessed it) BANG! several weeks are now spent learning to use the lathe, converting it to CNC, and adding code to my MillDroid CNC application (which by now was becoming AWESOME). My metal shop was now becoming a serious threat to humanity as I built up cabinets of the standards, micrometers, saws, windmills, grinders and all the other terrific things that suck up hobby money and time like a black hole. But now I was getting very productive….