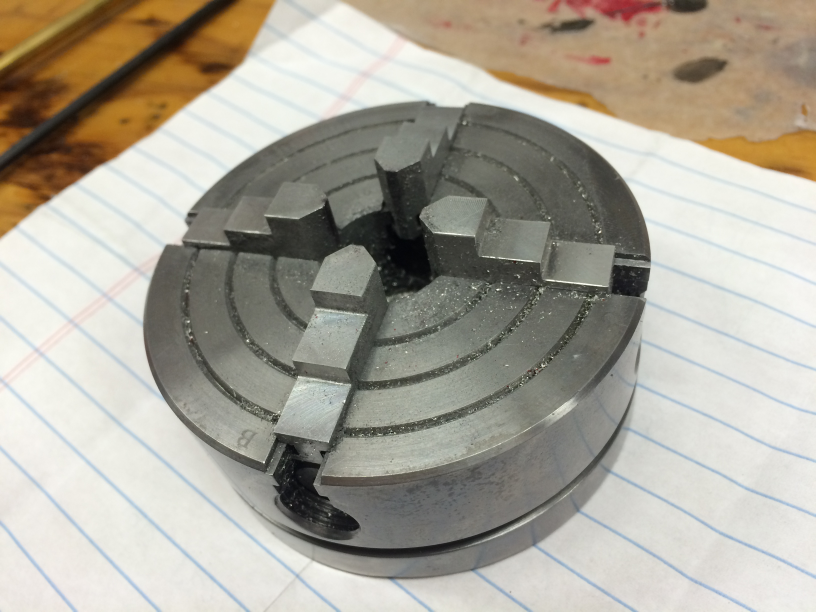

I’d already made soft jaws for most of my holding tools except for the Sherline Chuck. These seemed to have tolerances a bit too tight for me but when I saw what Sherline charged for a set I decided to take on the project.

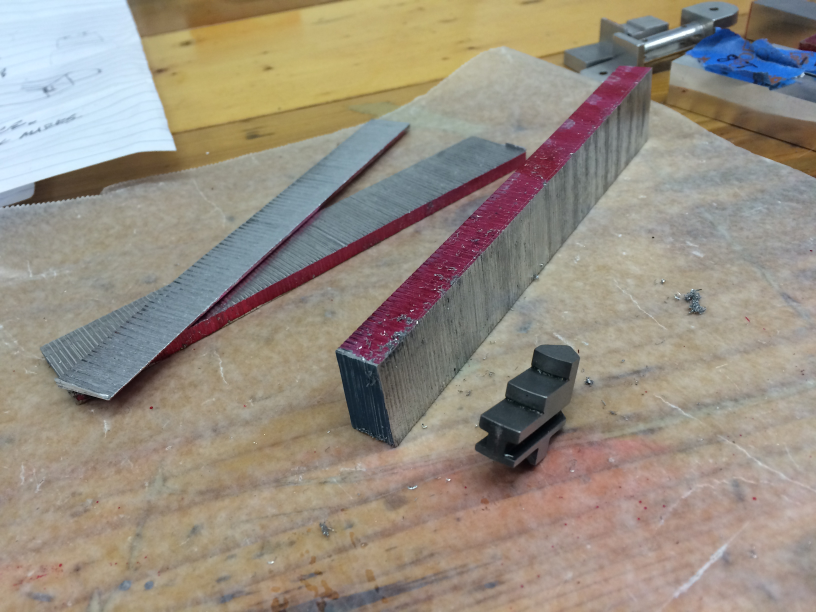

The originals are made of hardened steel and dented the aluminum I was working so I would make mine from aluminum 6061.

I rough cut some aluminum plate with my bandsaw.

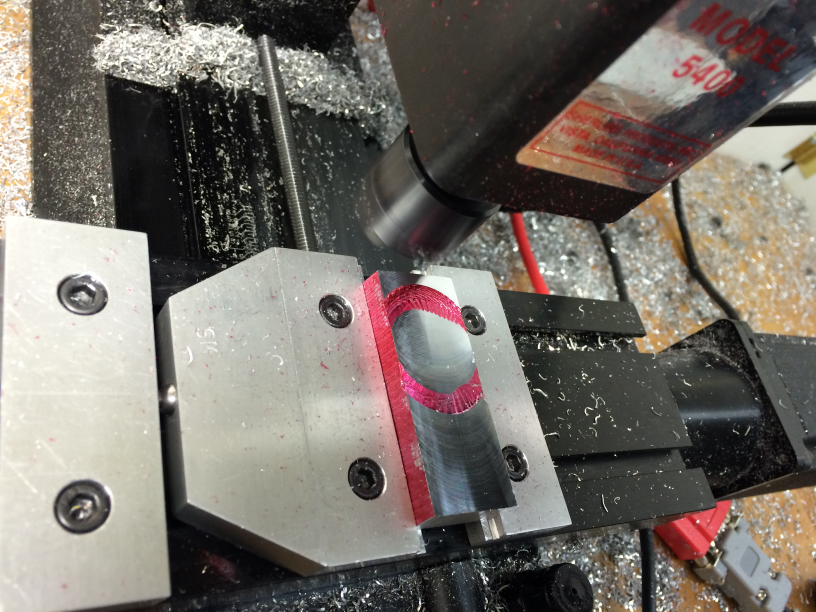

I originally tried cutting a 6 inch aluminum blank, flycutting it in one pass. The aluminum was only supported by the long edges. This was a bad idea. As the flycutter passed over the center of the aluminum bar I heard a vibration–it was the aluminum bar vibrating up and down in the center! The amplitude of the vibration increased until it slammed against the flycutter and tore loose from the vise. Fortunately the carbide flycutter didn’t shatter but it dug horribly into the aluminum.

I then cut the long bar into smaller two inch pieces to make a more stable piece for milling. I was able to facemill the bad cuts out of that bar as well.

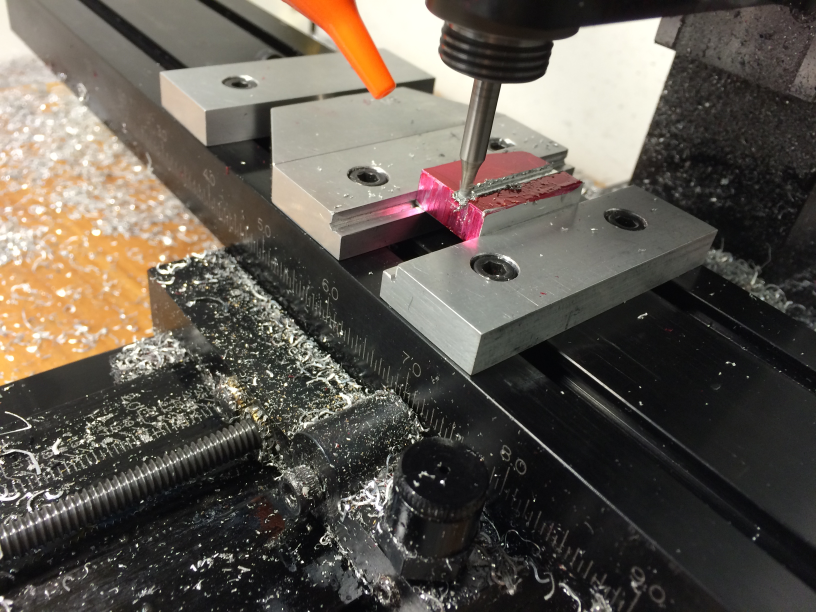

Milling out the side channels with a 1/16″ end mill. Nice and slow….those little end mills break easily if pushed too hard. Plenty of air to clear chips and WD-40 to lubricate the cutter every few passes.

I made quite a few “test-fits” of these, double-checking the measurements with a micrometer often because of the tight fit in the Chuck.

It was a nice challenge because of the very accurate fit that the jaws required. Here are the finished soft jaws along with one of the original hard steel jaws. I actually made five so I would have a spare. Being soft, I expect to damage one at some time.